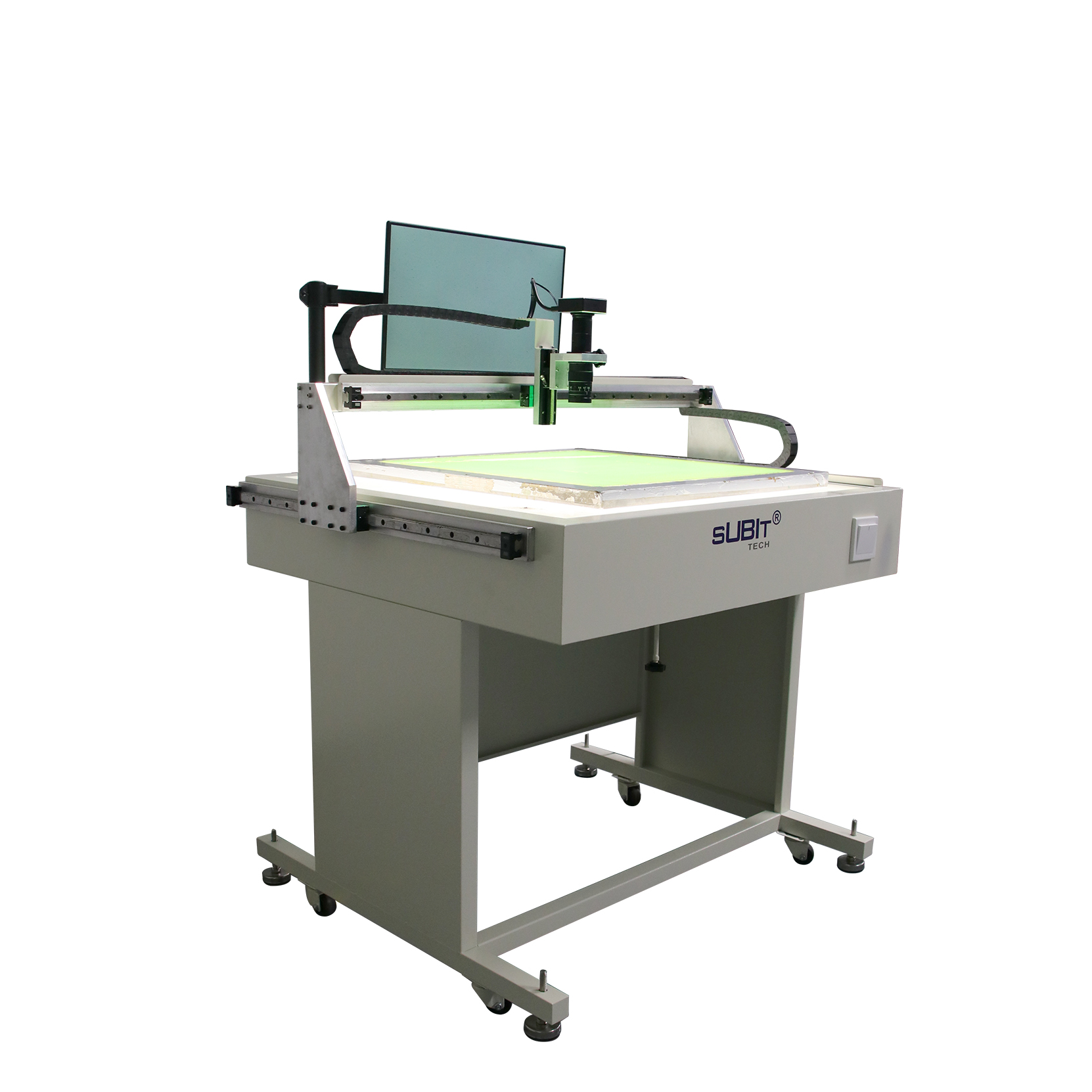

Semi-automatic Flying Probe First-article Detecting Machine

FAl-980 is a piece ofintelligent test terminal equipmentsubject to independent R&D and production by Jiedeng.ltsolves the problems, such as long time, high labor cost,incomplete test coverage, high error probability anddifficulty in tracing in the manufacturing process of theSMT manufacturing shop of the electronics factory.It can be used to detect the initial workpiece of solderpaste board(printing solder paste, and then pasting theelement),paste board(pasting double faced adhesive tape,and then pasting the element), red gum board (printing redgum, then pasting the element)and other types of plates.The detection types cover informative errors(such as BOMdosage error, position repetition, no definition of XYcoordinates and multiple definitions), manufacturabilityproblems(such as circuit board excessive pasting, missingparts, wrong parts,reverse direction, rollover and rotationand electrical characteristics of components, such asresistance,capacitance and inductance(usually incomingmaterial error).

The core hardware of JD-FAl includes computer,LCRbridge and HD scanner. They're subject to perfectcombination by the integrating self-developed softwaresystem to achieve fast and accurate measurement ofresistance,capacitance and inductance and conductautomatic appearanceinspection oflc chip, diode, audionand other originals with silk-screen.

Equipment Parameter

1 | Circuit board detected

| Circuit board in front of the SMT furnace (solder paste board, paste board and red gum board)

|

2 | Detection method

| Visual inspection of air paste position |

As for resistance, capacitance and inductance, the LCR bridge measurement is used | ||

As for IC and audion, the automatic optical character checking is used. | ||

The diode polarity can be distinguished and LED can be turned on. | ||

The average detection speed is 3s/element in accordance with the operator's proficiency, and the solder paste board is slow. | ||

3 | Scanner | Professional HD linear CCD scanner |

The highest definition: 600DPI~4800DPl | ||

The average scanning speed is 30s/PCS based on the PCBA size | ||

4 | LCR bridge | Test frequency: 20Hz~300KHz |

Minimum measurement of R/C, R: 0.05Ω: C: 0.1pF | ||

Basic precision: 0.05% | ||

Measuring display scope: R: 0.01m ohms-99.9999M ohms L: 0.01nH~9999.9HC:0.00001pF~9.9999F The testing software automatically controls the selection of measuring gear and parameters | ||

5 | Programming mode | Quickly importing BOM form and XY coordinates as well as matching with the scanning pattern |

Automatically extracting the element specification information from material | ||

Supporting two-sided coordinate import and selecting one side for detection | ||

Automatically identifying and marking the air paste position | ||

Interception by the box for optical character detection | ||

6 | Inspection result display | 23 inches of LCD and OK/NG sound and light hin |

7 | PCB size range | Maximum: 420mm x 310mm (the larger size shall be customized) |

8 | PCB± lower clear height | PCB upper part: 28mm PCB lower part 50mm |

9 | Voltage and power | AC220V 50/60HZ less than 1.5KVA |

10 | Equipment dimension &weight | 1160mm x 800mm x 1100mm (W*D*H)/230kgs |