News Center

Manual Type Stencil Inspection Machine: Precision Solution for SMT Quality Control

2025-09-04

2025-09-04 216

216

In the Surface Mount Technology (SMT) industry, the quality of stencils directly determines the accuracy of solder paste deposition, which in turn affects the reliability of electronic products. As a professional provider of SMT auxiliary equipment, Shenzhen Subite Technology Co., Ltd. (hereafter referred to as "Subite Technology") has launched the Manual Type Stencil Inspection Machine—a cost-effective, easy-to-operate tool designed to help manufacturers detect stencil defects efficiently and ensure production quality.

Core Functions of the Manual Type Stencil Inspection Machine

The Manual Type Stencil Inspection Machine focuses on solving common stencil problems such as aperture blockage, deformation, missing holes, and size deviation. Its key functions include:

Aperture Size Measurement: Equipped with a high-precision optical lens and digital measuring system, it can accurately measure the length, width, and diameter of stencil apertures, with a measurement accuracy of up to ±0.001mm.

Defect Detection: By magnifying the stencil surface (magnification range: 10x-100x), operators can clearly observe defects like aperture burrs, residual solder paste, and edge wear, and mark problematic areas in real time.

Position Deviation Check: With a built-in coordinate positioning system, the machine helps verify whether the relative position of apertures matches the design drawing, avoiding errors caused by stencil misalignment.

Data Recording: It supports manual input of inspection data (e.g., stencil model, inspection date, defect type) and generates simple inspection reports, facilitating traceability and quality analysis.

Advantages of Subite Technology’s Manual Type Stencil Inspection Machine

Compared with fully automatic stencil inspection machines (which are often expensive and require complex maintenance) and traditional manual inspection (relying on naked eyes and low efficiency), our Manual Type Stencil Inspection Machine has distinct advantages:

High Cost-Effectiveness: At a fraction of the cost of automatic equipment, it meets the basic inspection needs of small and medium-sized SMT factories, laboratories, and maintenance workshops.

Easy Operation: The user-friendly interface (with clear buttons and a LCD display) requires no professional technical background—operators can master the usage within 30 minutes of training.

Flexible Adaptability: It can accommodate stencils of various sizes (maximum stencil size: 600mm×600mm) and materials (steel, nickel, polyester), eliminating the need for frequent fixture replacement.

Portable Design: With a compact structure (size: approximately 500mm×400mm×300mm) and light weight (about 15kg), it can be easily moved to different workstations, saving workshop space.

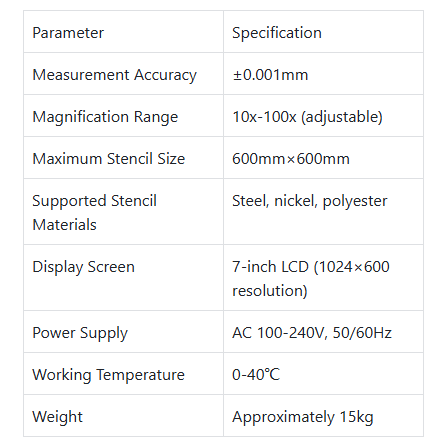

Technical Specifications

Application Scenarios

The Manual Type Stencil Inspection Machine is widely applicable in:

Small and medium-sized SMT manufacturing plants (for pre-production stencil verification and in-process stencil maintenance).

Electronic product maintenance workshops (for inspecting reworked or customized stencils).

R&D laboratories (for testing prototype stencils and optimizing aperture designs).

Stencil production factories (for final quality inspection of finished stencils before delivery).

About Shenzhen Subite Technology Co., Ltd.

Founded with a focus on "providing reliable SMT auxiliary solutions," Subite Technology has accumulated over 10 years of experience in the R&D and production of SMT equipment. Our team of engineers (with an average of 8 years of industry experience) continuously optimizes product performance based on customer feedback. For the Manual Type Stencil Inspection Machine, we provide:

1-year free warranty (covering parts and labor).

On-site installation and training services (available in mainland China).

Customization options (e.g., adjusting magnification, expanding stencil size compatibility) to meet specific customer needs.

Timely after-sales support (response within 24 hours for technical inquiries).

Contact Us

If you are looking for a practical, cost-effective stencil inspection solution, or want to learn more about the Manual Type Stencil Inspection Machine, please contact us.

Previous: Screen Printing Squeegee Grinder Buying Guide Next: A Quick Guide to Choosing Your Automatic Squeegee Blade Inspection Machine